Discover how the Impacts of Electric Vehicles on Car Manufacturers are reshaping the auto industry. As EVs go mainstream, legacy brands face massive overhauls in production, supply chains, and technology. Learn why adaptation is no longer optional—it’s survival in this electric revolution.

The Impacts of Electric Vehicles on Car Manufacturers extend beyond factories—redefining R&D budgets, workforce skills, and even dealership models. As EV demand surges, automakers must pivot faster than ever or lose ground to agile competitors.

Rising climate urgency and strict global emissions regulations are accelerating this shift. Governments are rolling out incentives and penalties, pushing automakers to pivot from fossil fuels faster than anticipated. The Impacts of Electric Vehicles on Car Manufacturers extend beyond technology—they’re rewriting entire business strategies.

This isn’t just about new cars; it’s a complete reimagining of 21st-century mobility. From supply chains to showrooms, the Impacts of Electric Vehicles on Car Manufacturers are reshaping every aspect of the industry.

Legacy Automakers Under Siege

The Impacts of Electric Vehicles on Car Manufacturers are hitting hardest at heritage brands. These industry titans, built on a century of internal combustion engine (ICE) dominance, now confront an existential crossroads. Where mastery of pistons and transmissions once ruled, today’s battle demands battery expertise and software prowess – a complete reinvention of corporate DNA.

The Trillion-Dollar Retooling Challenge

From factory floors to R&D centers, the Impacts of Electric Vehicles on Car Manufacturers trigger seismic operational shifts:

- Assembly lines redesigned for skateboard platforms

- Supply chains pivoting from mechanical parts to lithium-ion cells

- Dealership networks adapting to over-the-air updates

This isn’t mere adaptation – it’s a capital-intensive revolution where hesitation means obsolescence.

Cultural Shockwaves in Detroit and Beyond

The Impacts of Electric Vehicles on Car Manufacturers extend beyond hardware into human capital:

- Mechanical engineers reskilling for power electronics

- Union contracts rewritten for battery plant workforces

- Leadership teams recruiting Silicon Valley talent

The ultimate test? Transforming institutional mindset while the EV clock ticks.

The New Competitive Landscape

As startups like Tesla and BYD rewrite the rules, traditional players face a brutal equation:

- $200B+ in combined EV investments by 2030

- 5-year windows to recoup ICE plant investments

- 2x faster product development cycles required

Survival now hinges on simultaneous evolution across technology, operations, and culture.

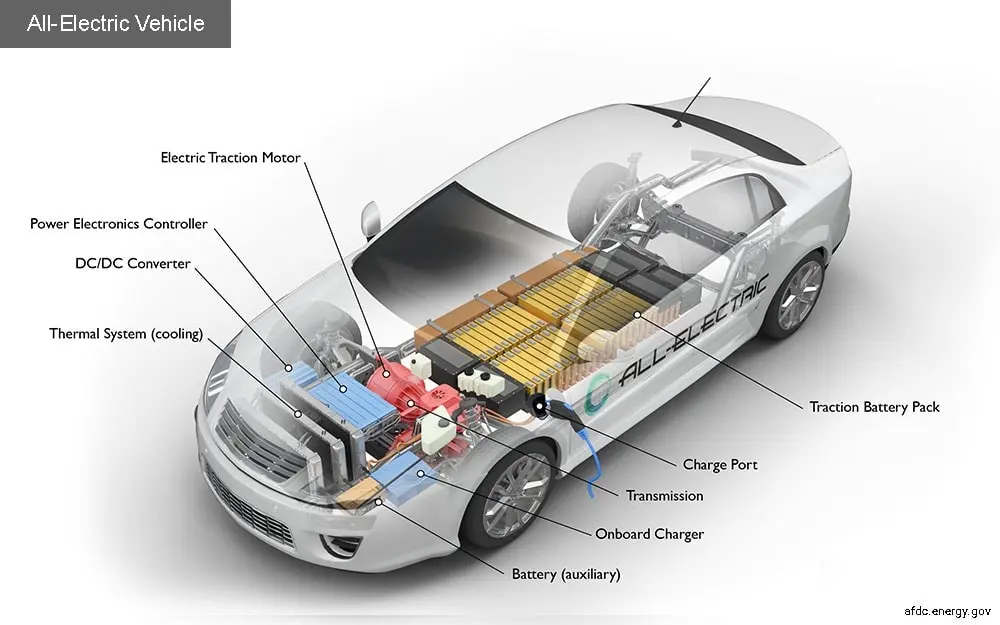

Radical Redesign of Production Systems

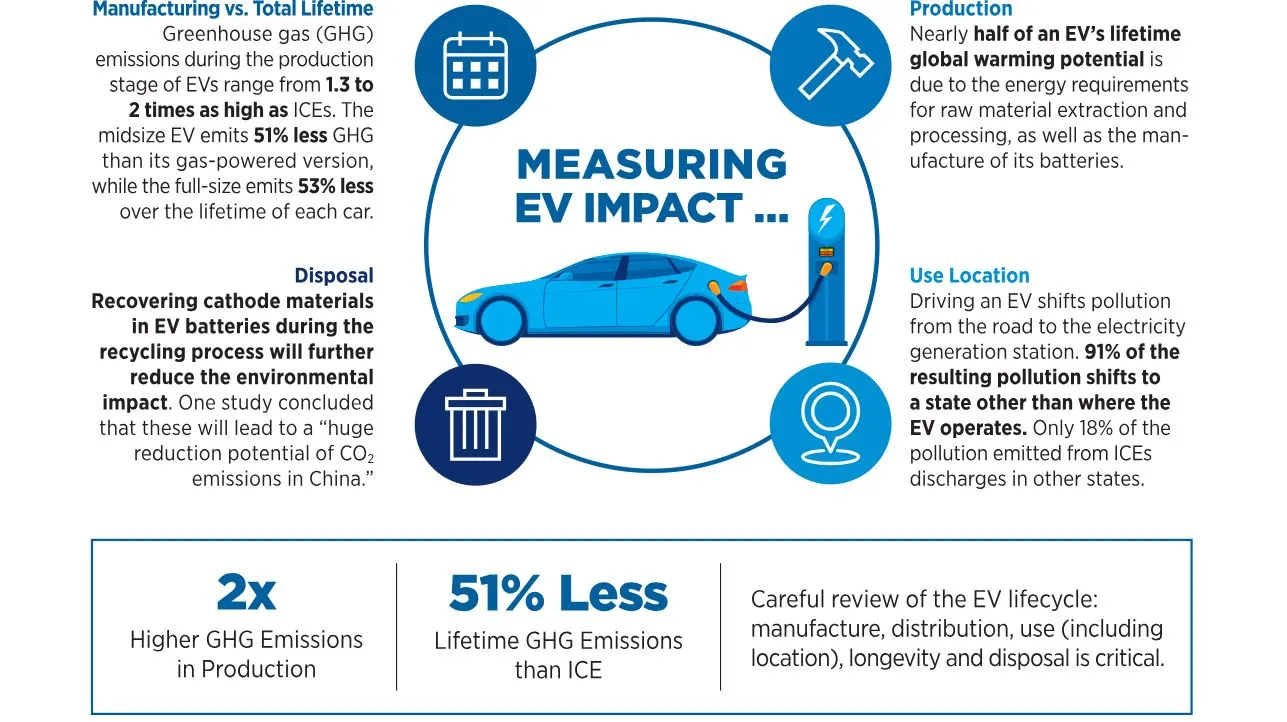

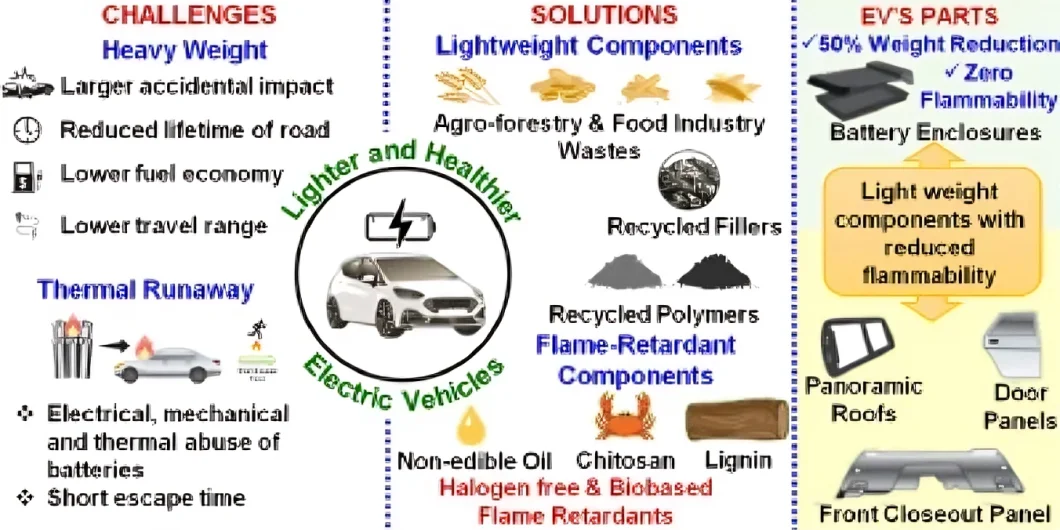

The Impacts of Electric Vehicles on Car Manufacturers begin with fundamentally different engineering. EVs eliminate hundreds of moving parts found in combustion engines, replacing them with advanced battery packs and simplified drivetrains. This shift forces automakers to completely reimagine production line layouts and quality control processes.

The Battery Technology Arms Race

Car manufacturers are now investing billions to overcome key EV challenges:

- Developing energy-dense battery chemistries

- Slashing charging times below 20 minutes

- Achieving 500+ mile ranges per charge

The Impacts of Electric Vehicles on Car Manufacturers have turned battery labs into strategic war rooms determining future market leaders.

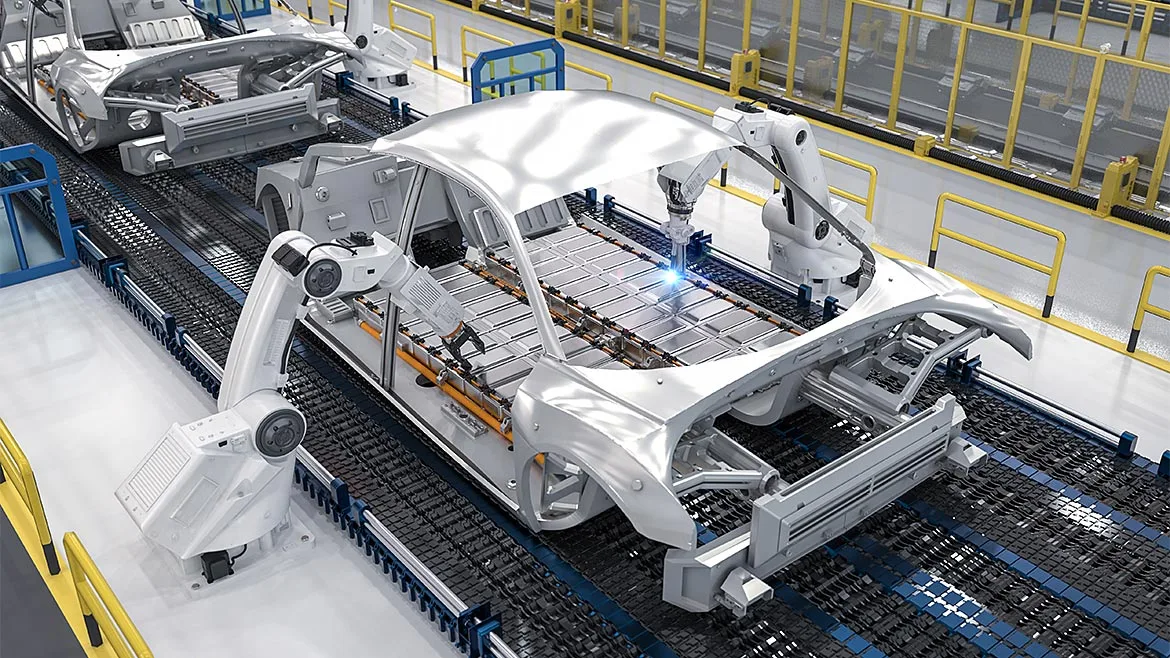

Gigafactories: The New Battlegrounds

The Impacts of Electric Vehicles on Car Manufacturers are most visible in the global gigafactory boom. These colossal battery plants represent the industry’s biggest infrastructure shift since Henry Ford’s assembly lines:

- Tesla’s Nevada gigafactory spans 5.3 million sq ft – equivalent to 100 football fields

- Volkswagen’s €20B battery push targets six European plants by 2030

- BYD’s blade battery factories dominate Asian supply chains with 60% cost reductions

These $2B+ facilities prove electrification isn’t just about cars – it’s an industrial revolution. For markets like Pakistan now embracing EVs, this infrastructure delivers game-changing benefits for drivers and manufacturers alike.

Workforce Revolution on Factory Floors

Traditional automakers face dual challenges:

- Retraining mechanical engineers in power electronics

- Upskilling assembly workers for battery module installation

The Impacts of Electric Vehicles on Car Manufacturers include complete workforce metamorphosis – where torque wrenches make way for diagnostic software.

The Critical Minerals Revolution

The Impacts of Electric Vehicles on Car Manufacturers are triggering a global scramble for battery materials. Lithium, cobalt, and nickel – once minor concerns – now dictate automakers’ geopolitical strategies. This shift has turned mining operations into strategic assets worth billions in investment.

Ethical Sourcing Challenges

Car manufacturers face unprecedented supply chain dilemmas:

- 70% of cobalt comes from high-risk artisanal mines

- Lithium demand will grow 40x by 2040 (IEA estimates)

- Child labor concerns force complete traceability systems

The Impacts of Electric Vehicles on Car Manufacturers include completely rewritten supplier standards.

Vertical Integration Strategies

Automakers are responding with bold moves:

- Tesla secures lithium rights in Nevada

- BMW invests $334M in battery recycling

- Ford controls nickel processing through Indonesian JVs

These Impacts of Electric Vehicles on Car Manufacturers create supply chains resembling tech companies more than traditional automakers.

The Circular Economy Imperative

With 12 million tons of batteries retiring by 2030:

- Recycling facilities become competitive advantages

- Second-life applications for used EV batteries emerge

- Closed-loop systems reduce virgin material needs

This represents perhaps the most transformative of all Impacts of Electric Vehicles on Car Manufacturers.

The Digital-First Customer Revolution

The Impacts of Electric Vehicles on Car Manufacturers extend far beyond factory floors into showrooms and apps. Today’s EV buyers demand Tesla-like digital experiences – from online configurators to augmented reality test drives. This forces legacy brands to completely rethink century-old dealership models.

Software Becomes the New Horsepower

Automakers are scrambling to meet new expectations:

- Over-the-air updates replacing recall notices

- Subscription features like BMW’s heated seats

- App ecosystems rivaling smartphones

These Impacts of Electric Vehicles on Car Manufacturers turn software engineers into star hires.

Charging Networks as Brand Battlegrounds

Forward-thinking manufacturers now view energy as a service:

- Tesla’s 45,000+ global Superchargers

- Mercedes’ $1B North American charging network

- GM’s dealer-installed Ultium Charge 360

Such investments prove the Impacts of Electric Vehicles on Car Manufacturers reach far beyond metal bending.

Maintenance Paradigm Shifts

With fewer moving parts, EV service focuses on:

- Battery health monitoring

- Software diagnostics

- Replacing your car battery for optimal performance

This creates both challenges and opportunities for dealer service centers.

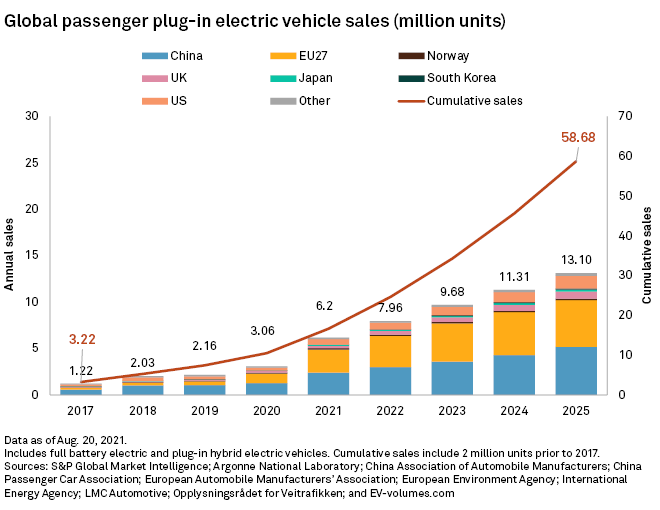

The EV Startup Disruption

The Impacts of Electric Vehicles on Car Manufacturers are most visible in today’s hyper-competitive landscape. While giants like Ford and Volkswagen invest billions in electrification, born-electric rivals like Tesla and Rivian are rewriting the rulebook. These agile newcomers operate without legacy factory constraints or dealer network obligations.

Innovation vs. Institutional Knowledge

Traditional automakers now face a paradoxical challenge:

- Their century of manufacturing expertise matters less

- Startup speed and software focus create advantages

- Investors value tech-style growth over traditional metrics

These Impacts of Electric Vehicles on Car Manufacturers have reshaped Wall Street’s auto sector valuations.

The Red Queen Race

The market now demands:

- 24-month vehicle development cycles (vs. traditional 60+ months)

- Vertical integration from mines to apps

- Continuous feature updates via software

This relentless pace represents the ultimate of all Impacts of Electric Vehicles on Car Manufacturers.

The Inevitable Electric Revolution

The Impacts of Electric Vehicles on Car Manufacturers represent nothing less than an industry rebirth – what began as battery-powered alternatives now demands complete reinvention of mobility’s DNA. This seismic shift goes beyond swapping engines for motors; it’s rewriting:

- Design philosophies (from aerodynamics to battery packaging)

- Manufacturing playbooks (gigacasting vs. traditional welding)

- Business models (subscription features, energy services)

With 60% of global auto sales projected to be electric by 2040 (BloombergNEF), the Impacts of Electric Vehicles on Car Manufacturers leave no room for half-measures. Brands clinging to ICE nostalgia face extinction, while those mastering software-defined vehicles will dominate tomorrow’s roads.

A Shift in Strategy

The Unavoidable EV Disruption

The Impacts of Electric Vehicles on Car Manufacturers have reached an inflection point, forcing legacy automakers to confront their ICE-dependent pasts. Brands that built empires on pistons and transmissions now face a stark choice – adapt or become obsolete in this electric era.

Billion-Dollar Bets on Electrification

Major manufacturers are making historic pivots:

- GM’s $35B EV investment targets 2035 carbon neutrality

- Ford’s $50B commitment aims for 50% EV sales by 2030

- Volkswagen plans 25+ new EV models by 2025

These Impacts of Electric Vehicles on Car Manufacturers represent the largest capital reallocation in auto history.

Redefining Automotive DNA

The transition goes beyond powertrains:

- Factories retooled for battery packs instead of engines

- Software teams now rival mechanical engineering

- Dealerships transform into “energy mobility hubs”

Such fundamental changes prove the Impacts of Electric Vehicles on Car Manufacturers are truly revolutionary.

The Supply Chain Overhaul

Supply Chain Upheaval

The Impacts of Electric Vehicles on Car Manufacturers are most disruptive in supply chains. EVs eliminate 200+ moving parts found in ICE vehicles, rendering entire supplier networks obsolete. This revolution favors battery chemists over transmission specialists, with lithium now more valuable than steel for automakers.

The Battery Gold Rush

Manufacturers are rewriting procurement rules:

- Tesla secures lithium directly from Nevada mines

- VW invests $30B in European battery plants

- Ford controls nickel supply through Indonesian partnerships

These Impacts of Electric Vehicles on Car Manufacturers create supply chains resembling tech firms more than traditional automakers.

New Industry Alliances

The shift demands unprecedented collaborations:

- GM-LG Energy Solution $2.3B Ohio battery plant

- BMW’s blockchain-tracked cobalt supply

- Car tuning for beginners now includes battery management systems

This transformation makes ethical sourcing as crucial as horsepower was yesterday.

Reimagining Manufacturing

Factory Floor Revolution

The EV transition demands complete plant overhauls, as traditional assembly lines built for engines make way for battery module production and electric motor integration. Manufacturers are installing AI-powered quality control systems and automated battery handling equipment that operate with surgical precision.

Workforce Transformation

This industrial shift has created:

- Intensive reskilling programs for ICE technicians

- Soaring demand for mechatronics engineers

- New hybrid roles blending software and mechanical expertise

The Digital Factory Era

Cutting-edge facilities now prioritize:

- Automated thermal management systems

These changes make EV plants resemble tech campuses more than traditional factories. - Real-time battery performance analytics

- Cloud-connected production monitoring

A Battle for Market Share

The Startup Disruption Effect

Born-electric companies like Tesla and Rivian have rewritten automotive rules, proving agility beats legacy in the EV revolution. Their direct-to-consumer models and tech-first approaches have forced century-old brands into uncharted territory, racing to match startup innovation speeds.

Legacy Automakers Fight Back

Traditional manufacturers are countering with:

- Bold EV sub-brands (like Ford’s Model e)

- Software-defined vehicle architectures

- Battery breakthroughs to close range gaps

The New Performance Metrics

Competitive advantage now hinges on:

- Carbon-neutral production commitments

The dashboard has become as critical as the drivetrain in today’s EV arms race. - Seamless over-the-air update systems

- AI-powered driver experiences

Environmental & Regulatory Pressures

The Regulatory Tipping Point

Global emissions mandates are accelerating the EV transition, with the EU banning new ICE sales by 2035 and California following by 2030. Manufacturers face a stark choice: lead the charge or become irrelevant as governments implement:

- Strict CO2 reduction targets

- ZEV mandate quotas

- Generous consumer tax credits

Green Manufacturing Revolution

Forward-thinking automakers are transforming operations through:

- Renewable-powered assembly plants

This full-value-chain approach separates climate leaders from laggards in the new automotive era. - Carbon-neutral battery production

- Closed-loop material recycling

Final Thoughts

The EV Revolution is Here to Stay

Electric vehicles represent more than a passing trend—they’re a complete transformation of the automotive industry. Manufacturers can no longer treat electrification as an experiment; it’s now a fundamental requirement for staying competitive.

Adapt or Risk Obsolescence

The choice is clear: embrace cutting-edge battery tech, sustainable manufacturing, and software-driven mobility, or fall behind. Leading automakers are already investing billions to secure their place in the electric future.

Winners and Losers Will Emerge

Companies that prioritize innovation and agility will dominate the next era of transportation. Those clinging to outdated ICE strategies face declining relevance in a market demanding zero-emission solutions. The race is on—and there’s no finish line in sight.

comprehensive analysis of the impact of electric vehicles on the automotive industry

digital twin technology and dimensional engineering

Cart is empty

Cart is empty

Leave A Comment